Pulse Roller Motor

( พัลส์ โรลเลอร์ ) DC Motor Roller

ระบบลูกกลิ้งลำเลียง

DRIVE

INTRODUCTION

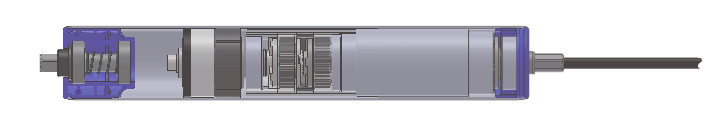

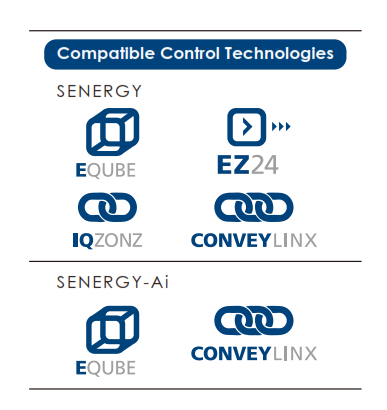

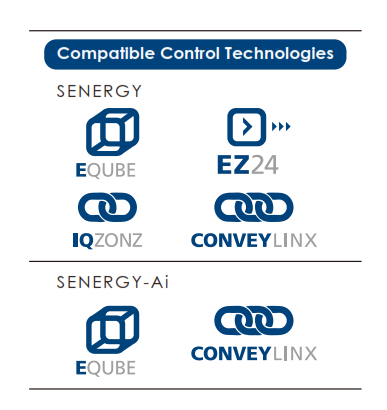

SENERGY

The SENERGY unique gearbox design and powerful brushless DC motor provides an extremely efficient means of delivering an amazing amount of torque and speed with the smallest amount of energy. Typically used in conveyors for Zero Pressure Accumulation or roller transportation. SENERGY Roller gearbox selection contains only 11 gearbox combinations to make ordering and keeping an inventory much more manageable. SENERGY’s range and performance characteristics are suitable for speeds between 2.0 to 304.1 m/min and starting torque up to an amazing 24.2 N·m.

Regardless of the project, type of conveyor, the weight or speed of the load you really only need one type of roller. SENERGY.

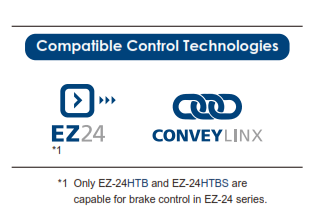

SENERGY-Ai

SENERGY-Ai is the world’ s first motor roller using a robust M8-4pin connector which is then connected to an external control of your choice. The hall-effect signals are digitally coded by a micro controller inside the motor, which makes it possible to communicate through only one pin to an external controller. The micro controller also digitally provides through the same pin complete roller part number containing the diameter and gearbox information, serial number, motor temperature and other information. The external control can read and analyze all this data for multiple functions such as precise speed and positioning control, full diagnostics such as over-temp, over-current, over-voltage and much mor to help with predictive maintenance.

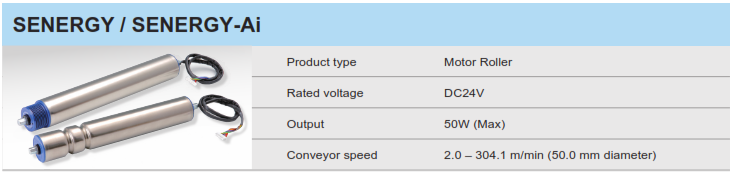

SENERGY / SENERGY-Ai

Product information

- Tube material: Mild steel, zinc plating / Stainless steel (SUS304)

- Roller diameter: 48.6 mm, 50.0 mm

57.0 mm, 60.5 mm - Min. roller length: Refer to the “Available minimum roller length table” below

- Max. roller length: 1000 mm *Contact us for longer than 1000 mm

- Cable length: 600 mm (SENERGY) / 1000 mm (SENERGY-Ai)

*Contact us for extension cables - Motor connector: JST (SENERGY) / M8-4pin (SENERGY-Ai)

- Operation: 0.5 sec ON / 0.5 sec OFF duty cycle (Minimum) or continuous within rated load

Optional spec.

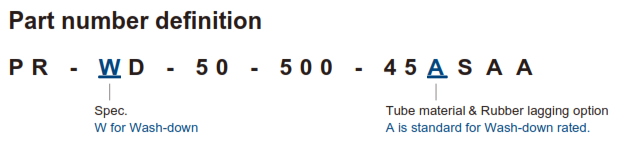

Wash-down rated

- IP rating: IP-66

- Material: All stainless made (Tube: SUS304, Side plate and shaft: SUS303)

- Roller diameter: 48.6 mm, 50.0 mm 57.0 mm, 60.5 mm

- Min. roller length: Refer to the “Available minimum roller length table“ below.

- Max. roller length: 1000 mm *Contact us for longer than 1000 mm.

- Cable length: 600 mm (SENERGY) / 1000mm (SENERGY-Ai)

*Contact us for extension cables - Motor connector: JST (SENERGY) / M8-4pin (SENERGY-Ai)

- Operation: 0.5 sec ON / 0.5 sec OFF duty cycle (Minimum) or continuous within rated load

Optional spec.

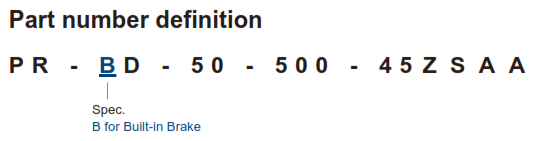

Built-in Brake

- Brake: Electromagnetic brake-Roller diameter: 48.6 mm, 50.0 mm 57.0 mm, 60.5 mm

- Min. roller length: Refer to the “Available minimum roller length” table below.

- Max. roller length: 1000 mm *Contact us for longer than 1000 mm.

- Cable length: 600 mm *Contact us for extension cables

- Operation: 0.5 sec ON / 0.5 sec OFF duty cycle (Minimum) or continuous within rated load

- Note: Not available with SENERGY-Ai

Optional spec.

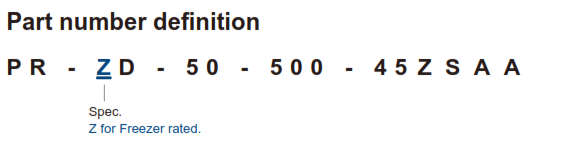

Freezer rated

- Applicable Temp: From 0°C down to -30°C (No condensation)

- Tube material: Mild steel, zinc plating / Stainless steel (SUS304)

- Side plate material: Aluminium

- Roller diameter: 48.6 mm, 50.0 mm 57.0 mm, 60.5 mm

- Min. roller length: Refer to the “Available minimum roller length table” below

- Max. roller length: 1000 mm *Contact us for longer than 1000 mm.

- Cable length: 600 mm *Contact us for extension cables

- Operation: 0.5 sec ON / 0.5 sec OFF duty cycle (Minimum) or continuous within rated load

- Note: Not available with SENERGY-Ai

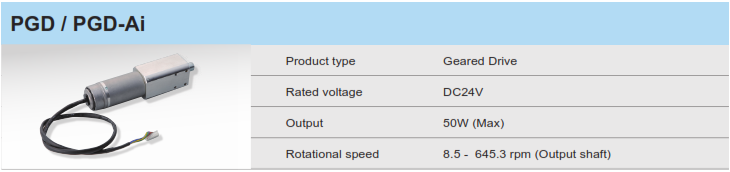

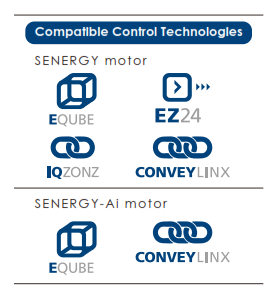

PGD / PGD-Ai

Pulse Geared Drive

Product information

- Mounting: M5 x 7 mm

- Shaft diameter: 16 mm

- Key: 5 x 5 x 25 mm

- Cable length: 600 mm (SENERGY motor) / 1000 mm (SENERGY-Ai motor)

*Contact us for extension cables - Motor connector: JST (SENERGY motor) / M8-4pin (SENERGY-Ai motor)

- Operation: 0.5 sec ON / 0.5 sec OFF duty cycle (Minimum) or continuous within rated load

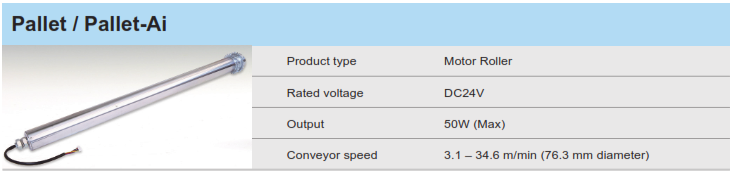

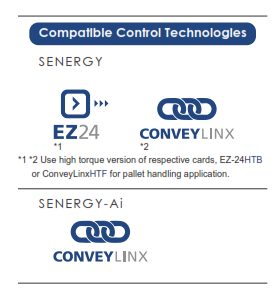

Pallet / Pallet-Ai

Product information

- Tube material: Mild steel, zinc plating / Stainless steel (SUS304)

- Roller diameter: 60.5 mm, 76.3 mm-Min. tube length: 450 mm

- Max. tube length: 1800 mm

- Cable length: 500 mm (Pallet) / 900 mm (Pallet-Ai)

PMD - Ai

Pulse Motion Drive

Product information

- Mounting: M4 x 4 pcs

- Shaft diameter: 8 mm

- Cable length: 1000 mm

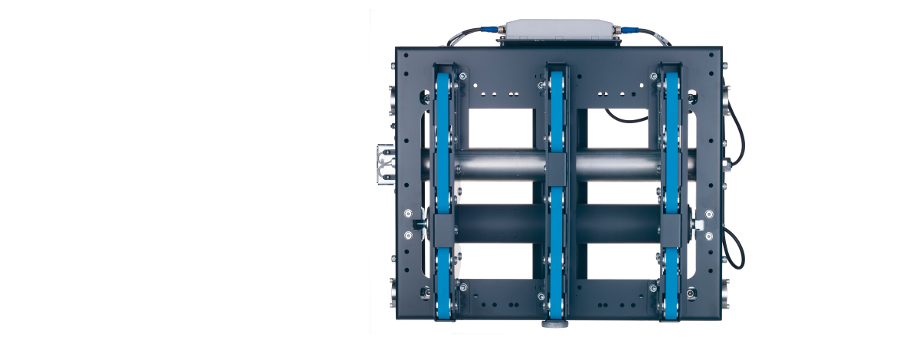

PDU - 90

Pulse Divert Unit 90 degrees

Product information

- Easy installation by mounting directly underneath conveyor frame

- Easy maintenance

- 2 SENERGY rollers for belt drive and lift up & down (No pneumatics)

- Customizable (W, L dimensions and number of belt units)

- Strong and oversized mechanical design

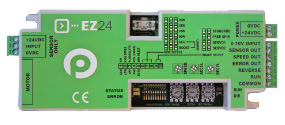

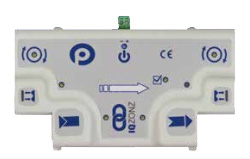

CONTROL

Drive Control

|

|

|

||

|---|---|---|---|---|

| Category | Description | E-Qube-N, E-Qube-P, E-Qube-Ai-P | EZ-24, EZ-24HTB & HTBS | IQ-ZONZ |

| Motor connection | Number of connectable motors | 1 | 1 | 2 |

| Sensor connection | Number of connectable sensors | 0 | 0 | 2 |

| Configuration setting | Speed, Braking, accel / decel, etc | DIP SW | DIP SW & RSW | Configuration software |

| Motor profile | ECO mode | ● | ● | ● |

| BOOST mode | – | ● | – | |

| BOOST-8 mode | – | ●*with EZ-24HTB & HTBS | – | |

| Speed control | Speed setting | 32 steps by DIP SW | 31 steps by DIP SW & RSW | 10 – 100% with software |

| Accel timer setting | 16 steps by DIP SW | 16 steps by DIP SW | 0.3 – 10 sec with software | |

| Decel timer setting | 16 steps by DIP SW | 16 steps by DIP SW | 0 – 10 sec with software | |

| Individual accel / decel setting | – | ● | ● | |

| Analog input speed control | – | ● | – | |

| Signal input speed change | ● | – | – | |

| Electrical braking | Standard (Dynamic brake) | ● | ● | ● |

| Servo lock | – | ● | – | |

| Free spin | – | ● | – | |

| Error | Motor protection | – | – | ● |

| Jam error detection | ● | ● | ●*using IQ-MAP (Globally only) | |

| Error signal output | – | – | – | |

| Conveyor logic | ZPA (Zero Pressure Accumulation) | – | – | ● |

| Marge control | – | – | – |

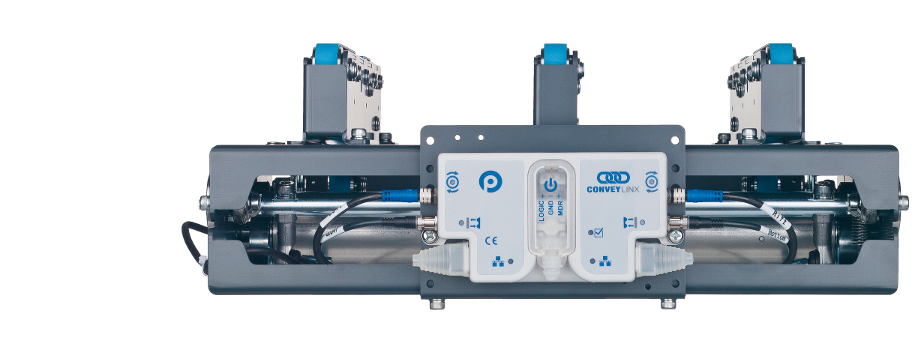

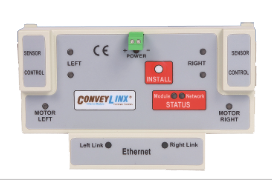

Networked Control

|

|

|

||

|---|---|---|---|---|

| Category | Description | ConveyLinx, ConveyLinx-HTF | ConveyLinx-Ai | MotionLinx |

| Motor connection | Number of connectable motors | 2 | 2 | 2 |

| Sensor connection | Number of connectable sensors | 4 | 4 | 2 |

| Configuration setting | Speed, Braking, accel / decel, etc | Software | Software | EtherCAT PLC |

| Motor profile | ECO mode | ● | ● | ● |

| BOOST mode | ● | ● | ● | |

| BOOST-8 mode | ●*with ConveyLinx HTF | ● | ● | |

| Speed control | Speed setting | ● | ● | ● |

| Accel timer setting | ● | ● | ● | |

| Decel timer setting | ● | ● | ● | |

| Individual accel / decel setting | ● | ● | ● | |

| Analog input speed control | ● | ● | ● | |

| Signal input speed change | ● | ● | ● | |

| Electrical braking | Standard (Dynamic brake) | ● | ● | ● |

| Servo lock | ● | ● | ● | |

| Free spin | ● | ● | ● | |

| Error | Motor protection | ● | ● | ● |

| Jam error detection | ● | ● | ● | |

| Error signal output | ● | ● | ● | |

| Conveyor logic | ZPA (Zero Pressure Accumulation) | ● | ● | ● |

| Marge control | ● | ● | ● | |

| Network | EtherNet/IP | ● | ● | – |

| Modbus TCP | ● | ● | – | |

| PROFINET | ● | ● | – | |

| EtherCAT | – | – | ● |