Conveyor System

Feeder and Conveyor

| TYPE | Inlet dia | Outlet dia | A | B | C | D |

| 168 | Ø 168 | Ø 168 | 160 | 140 | AS PER CUSTOMER REQUIREMENT | D = A+B+C |

| 219 | Ø 219 | Ø 219 | 180 | 160 | ||

| 273 | Ø 273 | Ø 273 | 220 | 180 | ||

| 323 | Ø 323 | Ø 323 | 220 | 220 |

Screw Conveyor Spares

Dust Collectors - Top & Ground Mounted

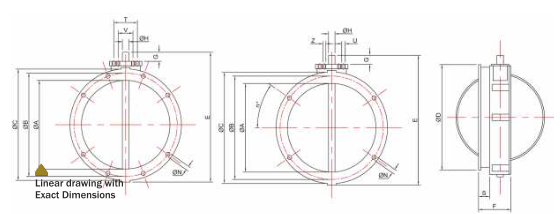

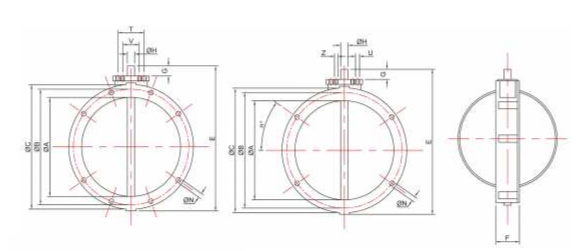

Butterfly Valve & Actuators

Most commonly used device for water, power / granular flow intercepting OR for isolating silo from screw or rest of the system, during maintenance work.

Salient Features

Available in variants of different diameters and material of construction for disc with option of manual or pneumatic actuators.

Light weight die cast aluminum body in single or double flange version, easy to fit and negligible maintenance. FIT IT & FORGET IT.

Single Flange Butterfly Valve

| TYPE | ØA | ØB | ØC | ØD | E | F | G | ØH | N | S | T | U | V | Z | Weight In kgs | |

| CBV/S/ 100/CN | 95 | 180 | 220 | 105 | 250 | 115 | 35 | 22×19 | 14 | 4 | 40 | 80 | M12 | 50 | M10 | 4 |

| CBV/S/ 150/CN | 150 | 200 | 228 | 163 | 290 | 115 | 35 | 22×19 | 14 | 4 | 40 | 80 | M12 | 50 | M10 | 5 |

| CBV/S/ 200/CN | 200 | 250 | 278 | 213 | 340 | 115 | 35 | 22×19 | 14 | 4 | 40 | 80 | M12 | 50 | M10 | 6.5 |

| CBV/S/ 250/CN | 250 | 300 | 328 | 263 | 390 | 115 | 35 | 22×19 | 14 | 4 | 40 | 80 | M12 | 50 | M10 | 7.5 |

| CBV/S /300/CN | 300 | 350 | 378 | 313 | 440 | 115 | 35 | 22×19 | 14 | 4 | 40 | 80 | M12 | 50 | M10 | 9 |

Double Flange Butterfly Valve

| TYPE | ØA | ØB | ØC | E | F | G | ØH | N | T | U | V | Z | Weight In kgs | |

| CBV/D/ 100/CN | 95 | 180 | 220 | 250 | 77 | 35 | 22×19 | 14 | 4 | 80 | M12 | 50 | M10 | 4 |

| CBV/D/ 150/CN | 150 | 200 | 228 | 290 | 77 | 35 | 22×19 | 14 | 4 | 80 | M12 | 50 | M10 | 5 |

| CBV/D/ 200/CN | 200 | 250 | 278 | 340 | 77 | 35 | 22×19 | 14 | 4 | 80 | M12 | 50 | M10 | 6.5 |

| CBV/D/ 250/CN | 250 | 300 | 328 | 390 | 77 | 35 | 22×19 | 14 | 4 | 80 | M12 | 50 | M10 | 7.5 |

| CBV/D /300/CN | 300 | 350 | 378 | 440 | 77 | 35 | 22×19 | 14 | 4 | 80 | M12 | 50 | M10 | 9 |

Bin Aerators

Salient Features

Made out of specially developed heat resistant. high tenacity silicon rubber with stainless steel strut for inert gas purging. Suitable to withstand temp. from-70 to 170 degree Celsius.

Paddle Level Sensors

PLS-type Bin Level Indicators have been specially developed & designed for eletric signaling by rotary action of minimum or maximum material level inside bins, hoppers or silos. i.e. Paddle remains stationary till the time powder is in contact & start rotating no sooner powder level goes down the paddle radius.

Salient Features

Suitable for variety of powders having bulk density in the range of 0.6 to 2T/M3.

Available in AC/DC voltage as per customer request.

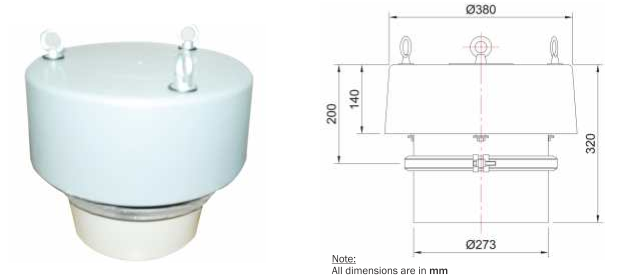

Pressure Relief Valve

Vital safety component for silos to avoid any damage and casualities at site, while loading/unloading if materail. Also known as Breather value, as it balances the pressure inside silos, breathing the air IN or OUT based on the requirement and safeguards the silos.

Salient Features

Spring loaded design helps controlling the pressure in the range of +1000mm to -120mm of H2O. Body material stainless steel with fiber top cover. Light weight & compact design suitable for 25-250 Tons capacity Sillo.